Pressure testing is a critical procedure in the oil and gas industry, designed to verify the strength, tightness, and overall integrity of new and existing pipelines, plant piping, and pressure-containing process equipment. This process ensures that systems can safely operate under their design conditions, preventing leaks, failures, and potential hazards. Governed by stringent industry codes like ASME B31, pressure testing is a cornerstone of safe and reliable operations.

What is Pressure Testing?

Pressure testing involves subjecting equipment or piping systems to internal pressure using a liquid (hydrostatic testing) or gas (pneumatic testing) to confirm their ability to withstand design pressures and detect any leaks. The scope includes:

- New installations: Verifying the integrity of newly constructed pipelines, plant piping, or equipment before commissioning.

- Existing systems: Revalidating operational systems during maintenance, turnarounds, or inspections to ensure continued safety.

- Pre-start-up leak tests: Conducted during commissioning or after turnarounds to ensure tightness at operating pressures.

The process applies to field- and shop-fabricated systems but excludes shop-fabricated equipment like vessels or heat exchangers purchased under specific material specifications, except for cases like fin-fan coolers.

Types of Pressure Tests

Several types of pressure tests are employed, each serving a specific purpose:

- Hydrostatic Test: Uses water or an approved liquid to pressurize the system. It is the preferred method due to its safety and ability to detect leaks effectively.

- Pneumatic Test: Uses air or an approved gas, typically requiring special approval due to the higher risks associated with stored energy in compressed gas. Strict safety protocols are followed.

- Pre Start-up Leak Test: Conducted at normal operating pressure to ensure tightness of flanged or threaded joints, often using inert gas or steam.

- Service Test: Performed at operating pressure with the service fluid to confirm system readiness.

- Strength Test: Verifies the system’s ability to handle design pressure, per applicable codes.

- Tightness Test: Focuses on detecting leaks at test pressure.

- Revalidation Test: Proves the integrity of existing systems, typically managed by the facility operator.

General Requirements for Pressure Testing

Pressure testing must adhere to rigorous standards to ensure safety and compliance. Key requirements include:

How to Check for Oil in Abrasives (Vail test)?

- Safety Protocols: Safe practices include isolating test areas, using calibrated gauges, and protecting against overpressure.

- Test Pressures and Durations: Determined by applicable standards for piping. The static head of the test liquid must be considered to avoid overstressing components.

- Overpressure Protection: Systems are safeguarded with relief valves set to activate at 5-10% above test pressure, sized per API RP 520. Bleed valves and isolation valves further mitigate risks.

- Test Procedures: Detailed plans must be prepared, specifying test conditions, documentation, and compliance with standards. For pneumatic tests, leak tests at 5-10 psi are mandatory per ASME SEC V.

- Non-Destructive Testing (NDT) Alternatives: In specific cases, NDT (e.g., radiographic or ultrasonic testing) may replace pressure testing, requiring approval and adherence to strict conditions, such as 100% weld inspection by ASNT Level III personnel.

Preparation for Pressure Testing

Proper preparation is essential for a successful test:

- Site Readiness: Approved test procedures must be on-site, and new piping systems cleaned per applicable standards.

- Equipment Exclusion: Sensitive components (e.g., pumps, relief valves, or instruments) are excluded to prevent damage.

- Isolation: Test sections are isolated using blind flanges or rated valves to ensure safety and prevent overpressure in untested systems.

- Vents and Drains: High-point vents and low-point drains are installed to facilitate filling and draining, minimizing entrapped air or fluid.

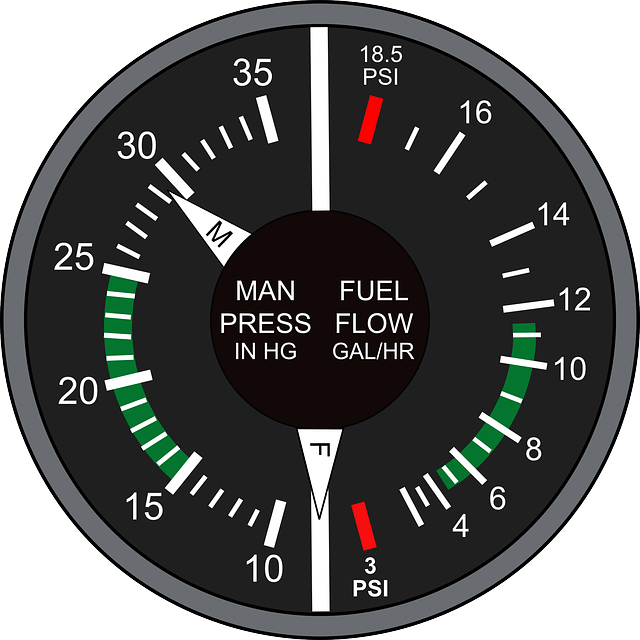

- Gauges and Recorders: Calibrated within one month, with test pressure within 30-80% of gauge range. At least two gauges are used for accuracy.

- Temporary Supports: Installed to handle test loads, especially for hydrostatic tests, and removed only after draining.

Conducting the Test

The testing process is methodical:

- Filling and Pressurizing: Fluid is injected at the lowest point to reduce air entrapment, with vents open. Pressurization occurs upstream of check valves.

- Safety Measures: After reaching test pressure, the area is isolated for 10 minutes before inspection. The test pump is disconnected, and isolation valves are managed to prevent accidental pressure changes.

- Valve Positioning: In-line valves not used for isolation are kept partially open to avoid damage.

- Documentation: Results are recorded, including test conditions and safety instruction sheets.

Post-Test Procedures

After testing, systems are carefully returned to service:

- Draining: Performed downstream of check valves with vents open to prevent vacuum formation. No fluid should remain in low spots.

- Fluid Disposal: Managed per environmental standards.

- Component Reinstallation: Temporary test items (e.g., blinds, manifolds) are removed, and excluded components reinstalled.

- Lay-Up: Systems are preserved per applicable standards to prevent corrosion or damage before operation.

Specific Testing Requirements

Different systems have tailored requirements:

- Plant Piping and Pipelines: Tested per applicable standards, ensuring compliance with design codes like ASME B31.3 or B31.4.

- Pressure Vessels: New vessels follow ASME SEC VIII; existing ones per relevant standards.

- Heat Transfer Equipment: Fin-fan exchangers and boilers have specific protocols, such as in-situ strength tests or ASME SEC I compliance.

- Tanks and Fire Systems: Governed by relevant industry standards.

- Utility and Building Systems: Potable water, sewers, and HVAC piping follow codes like UPC or applicable standards.

Challenges and Considerations

Pressure testing presents challenges, including:

- Safety Risks: Pneumatic tests carry higher risks due to gas compression, necessitating strict controls.

- Environmental Concerns: Proper disposal of test fluids is critical to avoid contamination.

- Coating Limitations: Internally coated systems require careful pressure management to prevent decompression damage.

- Freezing Risks: Cold ambient temperatures may freeze test media, requiring protective measures.

Conclusion

Pressure testing is an indispensable process for ensuring the safety and reliability of pipelines and process equipment in the oil and gas industry. By adhering to comprehensive standards, employing rigorous preparation, and following precise execution and post-test protocols, operators can confirm and confirm system integrity and prevent operational failures. Whether for new installations or existing infrastructure, pressure testing remains a vital practice in maintaining the high safety and performance standards demanded by the industry.