Introduction

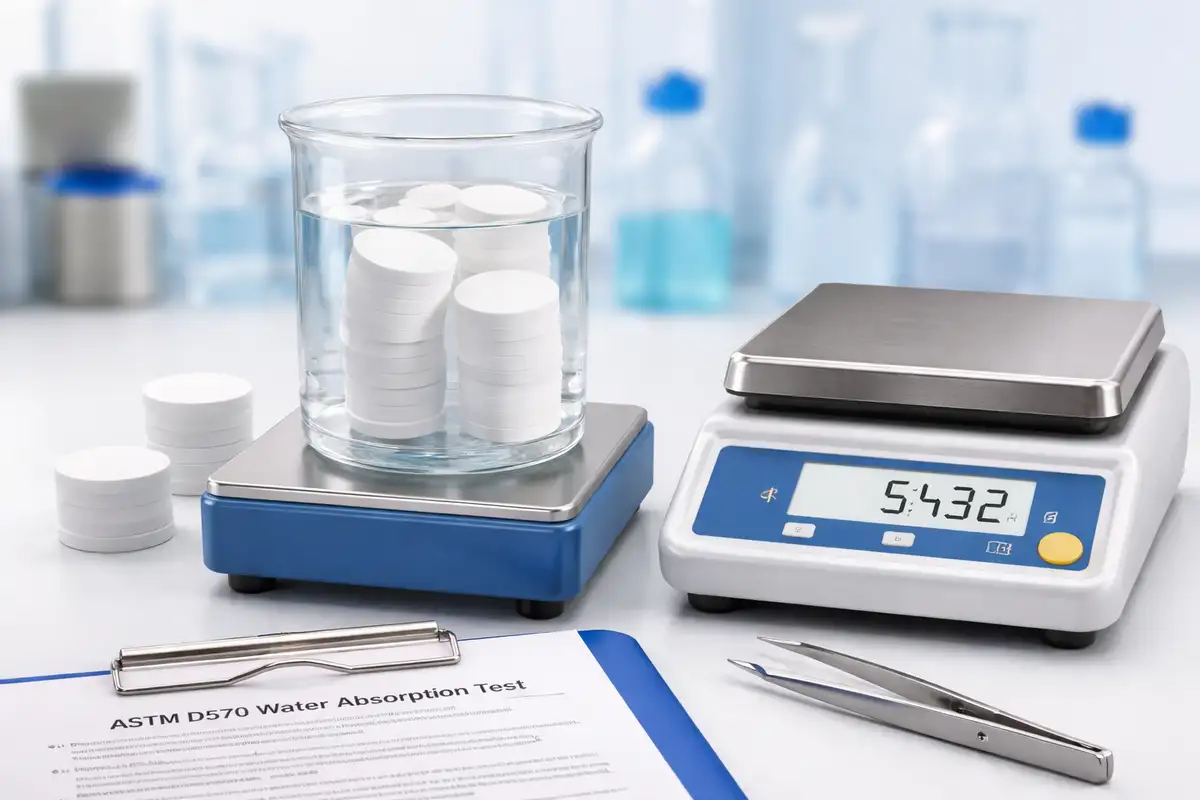

Water absorption is one of the most critical physical properties of plastic materials. The ASTM D570 – Standard Test Method for Water Absorption of Plastics defines the procedure for determining the rate and amount of water absorbed when plastics are immersed under controlled conditions.

This test is widely used in quality control, material selection, and performance evaluation for engineering plastics, laminated materials, molded products, rods, sheets, and tubes.

This guide explains the scope, specimen preparation, conditioning, immersion procedures, calculations, and reporting requirements in a practical and easy-to-understand format.

Scope of ASTM D570

ASTM D570 applies to:

- Cast plastics

- Hot-molded plastics

- Cold-molded resin products

- Laminated plastics

- Rods and tubes

- Sheets ≥ 0.13 mm thickness

The test determines the relative rate of water absorption when specimens are immersed in water.

It is technically equivalent to ISO 62 – Plastics: Determination of Water Absorption.

Why Water Absorption Testing Is Important

Water absorption affects several important properties of plastics:

- Electrical insulation resistance

- Dielectric properties

- Mechanical strength

- Dimensional stability

- Appearance and warping

- Structural integrity

Moisture content is especially critical in applications involving:

- Electrical components

- High-humidity environments

- Submerged service conditions

- Structural polymer components

For laminated plastics, water absorption may vary through surfaces and edges, making this test essential for uniformity control.

Apparatus Required

- Analytical balance (accuracy 0.0001 g)

- Drying oven capable of maintaining:

- 50 ± 3°C

- 105 to 110°C

Test Specimen Requirements

Molded Plastics

- Disk: 50.8 mm diameter

- Thickness: 3.2 mm

- Thickness tolerance:

- ±0.18 mm (hot molded)

- ±0.30 mm (cold molded or cast)

ISO Specimen (Equivalent to ISO 62)

- 60 × 60 × 1 mm

Sheets

- 76.2 mm × 25.4 mm × thickness

Rods

- 25.4 mm long (≤25.4 mm diameter)

- 12.7 mm long (>25.4 mm diameter)

Tubes

- Full section if <76 mm ID

- Rectangular specimen if ≥76 mm ID

All specimens must:

- Have smooth edges

- Be free from cracks

- Be measured to 0.025 mm precision

Conditioning Before Immersion

Three specimens must be conditioned.

Standard Conditioning

- Dry at 50 ± 3°C for 24 hours

- Cool in desiccator

- Weigh immediately (0.001 g accuracy)

Alternative Conditioning

For materials unaffected by higher temperatures:

- Dry at 105–110°C for 1 hour

ASTM D570 Test Procedures

1️⃣ 24-Hour Immersion (Most Common Method)

- Immerse specimens in distilled water

- Temperature: 23 ± 1°C

- Duration: 24 hours

- Remove and wipe surface water

- Weigh immediately

This method is used for comparison between plastics.

2️⃣ Two-Hour Immersion

Used for:

- Thin specimens

- Fast-absorbing plastics

Immersion time: 120 ± 4 minutes

3️⃣ Long-Term Immersion (Saturation)

- Initial 24-hour immersion

- Continue immersion

- Weigh weekly, then every 2 weeks

- Stop when weight increase <1% of total gain or <5 mg

This determines saturation water content.

4️⃣ Boiling Water Methods

Two-hour boiling immersion

- Boil in distilled water

- Cool 15 minutes in room-temperature water

- Weigh immediately

30-minute boiling immersion

- Used for high absorption materials

5️⃣ 50°C Immersion

- 48 hours at 50°C

- No cooling before weighing

Calculation of Water Absorption

Percentage Increase in Weight

WaterAbsorption(%)=DryWeightWetWeight−DryWeight×100

Reported to nearest 0.01%.

If Soluble Matter Is Lost

If reconditioning shows weight loss:SolubleMatter(%)=ConditionedWeightConditionedWeight−ReconditionedWeight×100

Total water absorption includes both absorbed water and soluble matter loss.

Diffusion Behavior

Water absorption in polymers follows a square-root-of-time relationship.

Time to reach 95% saturation depends heavily on thickness:

| Thickness (mm) | Time to 95% Saturation |

|---|---|

| 1 mm | 100 hours |

| 3.2 mm | 1,000 hours |

| 10 mm | 10,000 hours |

| 25 mm | 62,000 hours |

Thicker materials require significantly longer saturation times.

Reporting Requirements

The test report must include:

- Specimen dimensions

- Conditioning time & temperature

- Immersion method

- Immersion duration

- % increase in weight

- % soluble matter loss (if applicable)

- Observations (warping, cracking, appearance change)

For long-term immersion, a graph of weight gain vs √time is required.

Precision & Repeatability

Interlaboratory data shows:

For materials with absorption >1%:

- Within lab variation: 2.33%

- Between lab variation: 4.89%

For materials <0.2% absorption:

- Within lab variation: 9.01%

- Between lab variation: 16.63%

No definitive bias statement can be made.

Key Takeaways

- ASTM D570 measures % weight gain due to water immersion.

- 24-hour immersion at 23°C is the most commonly used method.

- Saturation testing requires long-term immersion.

- Thickness strongly affects absorption rate.

- Results are critical for electrical, mechanical, and dimensional performance.

- Equivalent to ISO 62 when ISO specimen dimensions are used.

FAQs

It measures the percentage of water absorbed by plastic materials after controlled immersion.

Water diffusion depends on specimen thickness; thicker materials take much longer to reach saturation.

Yes, when the ISO specimen size (60 × 60 × 1 mm) is used.

The 24-hour immersion at 23°C.