Complete Guide for Field and Laboratory Inspection

By Pritam Singh, QC Coating Inspector

When inspecting rigid plastics, FRP (Fiber Reinforced Plastic), or composite components in oil & gas, chemical plants, or storage tanks, hardness verification is often required for quality control.

The most commonly used method is:

ASTM D2583 – Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

This article explains the test principle, equipment, procedure, and practical inspection guidance.

Purpose of ASTM D2583

ASTM D2583 determines the indentation hardness of:

- Reinforced rigid plastics (FRP, GRP)

- Non-reinforced rigid plastics

- Thermoset laminates

- Sheet molding compounds (SMC)

- Bulk molding compounds (BMC)

It is widely used for:

✔ Production quality control

✔ Field inspection of fabricated parts

✔ Cure verification of FRP systems

✔ Comparing hardness consistency

The test is quick, portable, and suitable for on-site use.

Principle of the Barcol Hardness Test

The test measures the depth of penetration of a hardened steel indentor into the material surface.

- The shallower the penetration → the harder the material

- The deeper the penetration → the softer the material

The hardness reading is displayed on a dial scale from 0 to 100.

Higher reading = higher hardness.

Barcol Impressor Models

Two models are commonly used:

- Model 934-1 → For harder plastics

- Model 935 → For softer plastics

Inspection Tip:

- If reading is above 90 with Model 935 → switch to Model 934-1

- If reading is below 20 with Model 934-1 → switch to Model 935

Values below 10 (Model 935) are considered unreliable.

Equipment Requirements

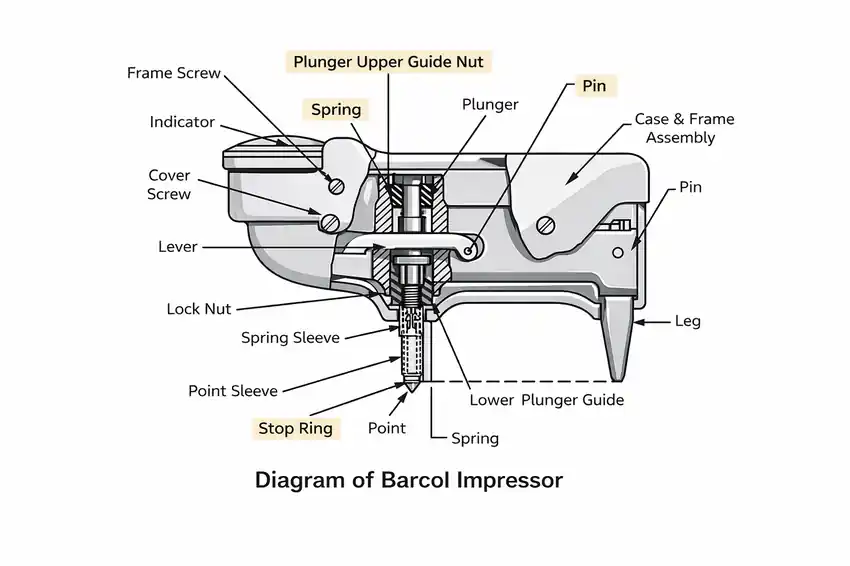

The Barcol Impressor includes:

- Hardened steel truncated cone indentor

- 26° cone angle

- Flat tip diameter approx. 0.157 mm

- Dial indicator with 100 divisions

Each dial division represents approx. 0.0076 mm indentation depth.

Calibration disks (hard and soft aluminum) must be used for verification.

Test Specimen Requirements

Specimen must:

✔ Be at least 1.5 mm thick

✔ Have smooth, defect-free surface

✔ Maintain minimum 3 mm distance from edges

✔ Maintain 3 mm spacing between indentations

Important:

Reinforced plastics show greater reading variation due to resin and fiber differences.

Conditioning Requirements

Specimens must be conditioned at:

- 23 ± 2°C

- 50 ± 10% Relative Humidity

- Minimum 40 hours (unless otherwise specified)

Testing should also be conducted under standard laboratory conditions.

Mechanical properties of rigid plastics can be affected by moisture exposure. For evaluating moisture sensitivity and dimensional stability, refer to our detailed guide on ASTM D570 – Water Absorption Test Method for Plastics (Complete Guide).

Step-by-Step Test Procedure

Step 1: Calibration

- Place the Impressor on a smooth glass plate.

- Press fully; reading should indicate 100.

- Verify with manufacturer’s hard and soft aluminum disks.

- If readings are outside range → instrument must be adjusted.

Testing without proper calibration invalidates results.

Step 2: Positioning

- Place specimen on solid, rigid support.

- Ensure indentor is perpendicular to surface.

- Avoid flexible backing (prevents false low readings).

Step 3: Apply Load

- Apply uniform downward pressure.

- Do not slide or scrape surface.

- Record maximum reading immediately.

Note: Some materials show drift after maximum reading.

Step 4: Number of Readings

Take minimum:

✔ 10 readings at different locations

Report average value rounded to nearest whole number.

Reporting Requirements

Report must include:

- Material identification

- Conditioning method

- Impressor model used

- Number of readings

- Average hardness value

- Date of test

- ASTM designation (D2583 − 13a)

Proper documentation ensures traceability.

Precision and Interpretation

Precision varies depending on material type.

For homogeneous plastics → lower variation

For reinforced plastics → higher variation

Hardness comparison between laboratories requires careful statistical evaluation.

The standard provides repeatability (Ir) and reproducibility (IR) guidance for Model 934-1.

Practical Applications in Oil & Gas

Barcol hardness testing is commonly used for:

✔ FRP tanks and piping

✔ Chemical storage vessels

✔ Composite structural components

✔ Cured epoxy/thermoset laminates

✔ Field cure verification

It is particularly useful during:

- Post-curing verification

- FRP installation inspection

- Repair quality control

Common Inspection Mistakes

❌ Testing on thin or flexible surface

❌ Skipping calibration

❌ Taking too few readings

❌ Testing too close to edges

❌ Using wrong Impressor model

These errors lead to inaccurate hardness values.

Limitations of ASTM D2583

- No direct ISO equivalent

- Not suitable for very soft elastomers

- Limited bias data

- Provides comparative, not absolute, hardness

It is a field-friendly control test, not a full mechanical property evaluation.

Conclusion

ASTM D2583 provides a quick and portable method for evaluating indentation hardness of rigid plastics and FRP components.

For inspectors, it is a valuable tool for:

✔ Production control

✔ Field verification

✔ Cure assessment

✔ Quality documentation

When properly calibrated and applied, it provides reliable comparative hardness data for rigid plastic materials.

FAQ

It measures indentation hardness of rigid plastics using a Barcol Impressor.

0–100 Barcol units.

Minimum 10 readings per specimen.

Yes, widely used for reinforced plastics and composites.

Without proper calibration using manufacturer disks, results are invalid.