Introduction

ASTM D1002 is a standard test method used to determine the apparent shear strength of single-lap-joint adhesively bonded metal specimens under tension loading. This test is widely used in industrial applications to evaluate the performance of metal-to-metal adhesive bonds.

The method provides a controlled and standardized way to compare adhesive systems, surface preparation methods, and bonding conditions.

Scope of ASTM D1002

This test method covers:

- Determination of apparent shear strength

- Adhesively bonded metal-to-metal joints

- Single-lap-joint specimens

- Testing under controlled preparation and loading conditions

The values are reported in SI units, with inch-pound units provided for reference.

Important Considerations Before Testing

The strength results obtained from adhesive tests depend heavily on bonding conditions. Therefore, the adhesive manufacturer must provide complete instructions for:

- Surface preparation procedures

- Cleaning and drying methods

- Mixing directions

- Application method and adhesive thickness

- Assembly conditions (temperature, humidity, open/closed assembly)

- Curing conditions (pressure, temperature, duration)

- Conditioning before testing

Without proper control of these variables, the test results may not accurately represent adhesive performance.

ASTM C177 – 97: Guarded Hot Plate Test Method Explained

Significance and Use

ASTM D1002 is primarily a comparative test method.

It is used for:

- Comparing adhesive systems

- Evaluating surface preparation methods

- Assessing bonding process variations

- Studying environmental durability

- Quality control testing

⚠️ Important:

The apparent shear strength values obtained from this test should NOT be used directly as structural design allowable values. Misuse of these values may lead to joint failure and safety risks.

Test Specimen Requirements

Specimen Configuration

The test uses a single-lap joint specimen consisting of two metal strips bonded with adhesive in an overlapping configuration.

Recommended Dimensions

- Metal thickness: 1.62 ± 0.125 mm

- Overlap length: 12.7 ± 0.25 mm

- Shear area determined by width × overlap length

The overlap length must not exceed limits that would cause yielding of the metal before adhesive failure.

Recommended Metal Types

The following metals are commonly used:

- Brass (ASTM B36)

- Copper (ASTM B152)

- Aluminum Alloy 2024-T3 (ASTM B209)

- Steel (ASTM A109)

- Stainless Steel Type 302 (ASTM A167)

- Titanium (ASTM B265)

Preparation of Test Joints

Surface Preparation

All edges must be:

- Smooth

- Free of burrs

- Machined true

- RMS 160 maximum

Surface cleaning must follow adhesive manufacturer instructions.

Adhesive Application

- Apply adhesive uniformly

- Control overlap length within ±0.25 mm

- Cure according to manufacturer specifications

Multiple specimens are typically prepared in panels and then cut into individual test specimens.

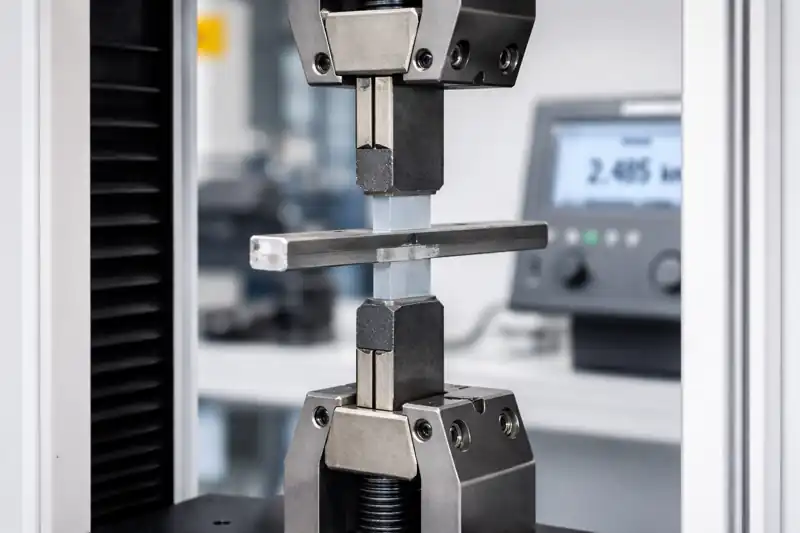

Testing Procedure

- Place specimen in self-aligning grips.

- Ensure long axis aligns with load direction.

- Apply tensile load at a rate equivalent to:

- 80–100 kg/cm² per minute of shear area

- Approximately 1.3 mm/min crosshead speed

- Continue loading until failure.

Calculations

Shear Strength Calculation

ShearStrength=ShearAreaLoadatFailure

Where:

Shear Area = Width × Overlap Length

Results are expressed in:

- kg/cm²

- psi

Reporting Requirements

The test report must include:

- Adhesive identification

- Metal type and thickness

- Surface preparation method

- Bonding conditions

- Adhesive thickness

- Overlap length

- Conditioning procedure

- Number of specimens tested

- Maximum, minimum, and average shear strength

- Type of failure (cohesive, adhesive, or metal failure)

Types of Failure Observed

During testing, failure may occur as:

- Cohesive failure (within adhesive)

- Adhesive failure (bond line separation)

- Substrate failure (metal yielding)

Recording the nature of failure is essential for proper interpretation of results.

Limitations of ASTM D1002

- Apparent shear strength may vary with adherend type

- Environmental conditions affect results

- Not suitable for direct structural design

- Precision and bias statement not fully established

The test should be interpreted carefully, especially when comparing different materials or joint configurations.

Key Takeaways

- ASTM D1002 measures apparent shear strength of metal-to-metal adhesive bonds.

- Uses single-lap joint configuration.

- Primarily a comparative quality control test.

- Not intended for direct structural design values.

- Surface preparation and curing conditions strongly influence results.

- Failure mode reporting is critical.

✅ FAQ

ASTM D1002 measures the apparent shear strength of single-lap adhesive bonds between metal specimens under tensile loading.

No. The results are comparative and should not be directly used as structural design allowable stresses.

Common metals include aluminum, steel, stainless steel, brass, copper, and titanium.

Failure may be cohesive (within adhesive), adhesive (bond line), or substrate (metal failure).

Surface preparation significantly influences bond strength and repeatability of results.