By Pritam Singh, QC Coating Inspector

In my 11 years of experience as a QC Coating Inspector in oil & gas projects, I have seen one common reason behind most coating failures — poor surface preparation. No matter how expensive the coating system is, if surface preparation is not inspected properly, failure is only a matter of time.

In this article, I am sharing the complete surface preparation inspection checklist that I personally follow on onshore and offshore oil & gas projects.

Why Surface Preparation Inspection Is Critical

In oil & gas facilities, steel structures are exposed to:

- Marine atmosphere

- High humidity

- Chemical exposure

- High temperature service

- Soil corrosion (for buried pipelines)

If surface preparation is not done and inspected properly, corrosion starts under the coating, leading to blistering, peeling, and premature failure.

Most projects follow standards from:

- NACE International

- SSPC

- ISO

As inspectors, it is our responsibility to ensure full compliance with these standards and project specifications.

1️⃣ Pre-Surface Preparation Inspection (What I Check First)

Before blasting starts, I always verify the following:

✔ Documentation Review

- Approved coating specification

- Surface preparation procedure

- Inspection & Test Plan (ITP)

- Calibration certificates of instruments

- Approved abrasive material details

✔ Steel Condition

- Check for oil & grease contamination

- Verify weld spatter removal

- Ensure sharp edges are rounded (minimum 2 mm radius)

- Confirm no visible lamination or surface defects

Skipping this step can create major problems later.

2️⃣ Environmental Condition Check (Very Important)

Before allowing blasting, I measure and record:

- Ambient temperature

- Steel surface temperature

- Relative humidity

- Dew point

I always ensure that the steel temperature is at least 3°C above the dew point.

If this condition is not satisfied, condensation may occur and cause flash rusting.

3️⃣ Surface Cleaning Before Blasting

If oil or grease is present, blasting will not solve the problem.

I ensure solvent cleaning is carried out as per:

- SSPC-SP 1

I normally perform a clean white rag test to verify contamination removal.

4️⃣ Abrasive Blasting Inspection Checklist

This is the most critical stage.

✔ Abrasive Material Check

Before blasting starts, I verify:

- Abrasive is clean and dry

- No oil contamination

- Proper size and type as per specification

- Conductivity or chloride test (if required)

Using contaminated abrasive can destroy the entire coating system.

✔ Surface Profile Measurement

After blasting, I measure the surface profile using replica tape or a surface profile gauge.

Reference standard:

- ISO 8503

Most oil & gas projects require 50–100 microns profile, but I always follow project specification.

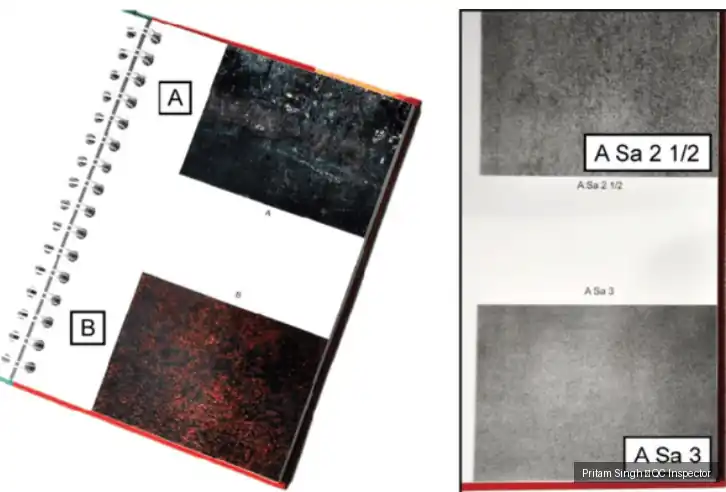

✔ Cleanliness Standard Verification

I compare the blasted surface with standard photographs as per:

- ISO 8501-1

- SSPC-SP 10

- SSPC-SP 5

I check carefully for:

- Complete removal of rust and mill scale

- No visible oil or dirt

- No embedded abrasive

- Uniform surface appearance

5️⃣ Post-Blasting Inspection (Before Coating)

This is where many inspectors make mistakes by rushing.

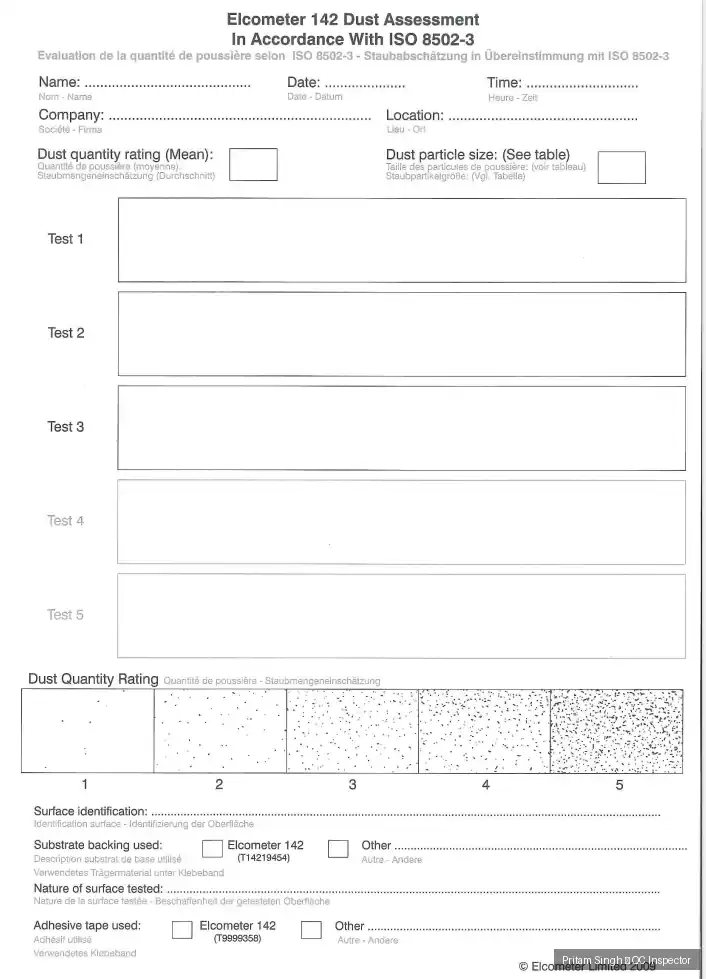

✔ Dust Level Test

I perform dust testing as per:

- ISO 8502-3

✔ Soluble Salt Test

Chloride contamination is a silent killer of coatings.

I conduct soluble salt testing to ensure the results are within project limits (commonly < 20 mg/m² for internal surfaces and < 40 mg/m² for external surfaces).

✔ Flash Rust Check

If blasting is done in humid conditions, I ensure no unacceptable flash rust is present before primer application.

6️⃣ Final Hold Point Before Primer Application

Before releasing the area for coating, I verify:

- Surface profile is within range

- Cleanliness meets required standard

- Environmental conditions are acceptable

- Inspection report is completed and signed

- Client approval obtained (if required)

I also ensure that coating is applied within the specified time window — usually within 4 hours in humid environments.

Common Surface Preparation Mistakes I Have Observed

- Ignoring dew point difference

- Delaying coating after blasting

- Not checking salt contamination

- Accepting sharp edges

- Using unapproved abrasive

These small mistakes can cause major failures later.

What I Include in My Surface Preparation Report

My inspection report always includes:

- Environmental readings

- Cleanliness standard achieved

- Surface profile measurements

- Salt contamination results

- Dust rating

- Inspector signature

Documentation is as important as inspection itself.

Conclusion

From my professional experience, I can confidently say that surface preparation inspection is the foundation of coating performance in oil & gas projects.

If this stage is controlled properly, coating life increases significantly, maintenance costs reduce, and plant reliability improves.

As inspectors, we are the last line of defense before coating application — and that responsibility should never be taken lightly.

FAQs

Typically 40–65 microns, but always follow project specification.

If steel temperature is close to dew point, condensation forms and causes flash rust.

ISO 8501-1 and SSPC-SP standards.

Usually within 4 hours, depending on humidity and specification.

From my experience, the most critical parameter is the dew point difference. The steel surface temperature must be at least 3°C above the dew point. If this condition is ignored, condensation can form and cause flash rusting, leading to coating failure.