Checking the pressure at a blasting nozzle is essential for maintaining efficiency, ensuring safety, and optimizing abrasive flow during sandblasting or abrasive blasting projects. Incorrect pressure can lead to poor performance or equipment damage. This step-by-step guide explains how to measure nozzle pressure accurately, focusing on the industry-standard method using a hypodermic needle pressure gauge.

Why Checking Blasting Nozzle Pressure Matters

Proper nozzle pressure ensures your blasting equipment operates at peak performance. Ideal pressure typically falls between 90–110 PSI (6.2–7.6 Bar), depending on the job. Too low, and you’ll lose efficiency; too high, and you risk wearing out components faster. Regularly checking pressure helps you avoid costly downtime and maintain consistent results.

Method 1: Using a Hypodermic Needle Pressure Gauge

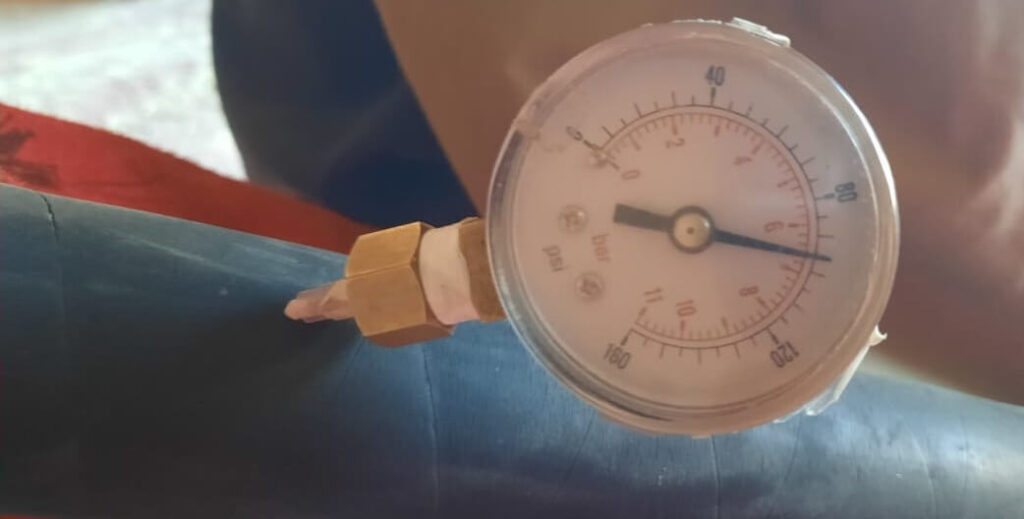

For the most reliable results, use a hypodermic needle pressure gauge. This method is widely recommended by professionals. Watch this quick YouTube Short for a visual demo: How to Measure Nozzle Pressure. Here’s how to do it:

Step 1: Get the Right Tool

Invest in a hypodermic needle pressure gauge, designed specifically for blasting nozzles. It’s affordable and ensures precise readings.

Step 2: Prepare the Blast Hose

Drill a small hole in the blast hose, about 6 inches (15 cm) from the nozzle holder. The hole should be slightly smaller than the needle to avoid leaks. Some hoses come with pre-installed test ports—use those if available.

Step 3: Measure the Pressure

Insert the needle probe into the hole. The gauge will instantly show the pressure at the nozzle. Record the reading to compare against the ideal range of 90–110 PSI.

Step 4: Seal the Hole

After testing, remove the gauge. For temporary use, cap the hole with a rubber plug. For a permanent fix, apply a hose repair kit to seal it securely.

Tips for Success

- Test pressure before each major job to ensure consistency.

- If readings are off, check for clogs or worn parts in the nozzle or hose.

- Always wear safety gear during testing.

Final Thoughts

Mastering how to check pressure at the blasting nozzle can save time and money. With a hypodermic needle pressure gauge and these steps, you’ll keep your blasting setup running smoothly. Optimize your process today!