Introduction

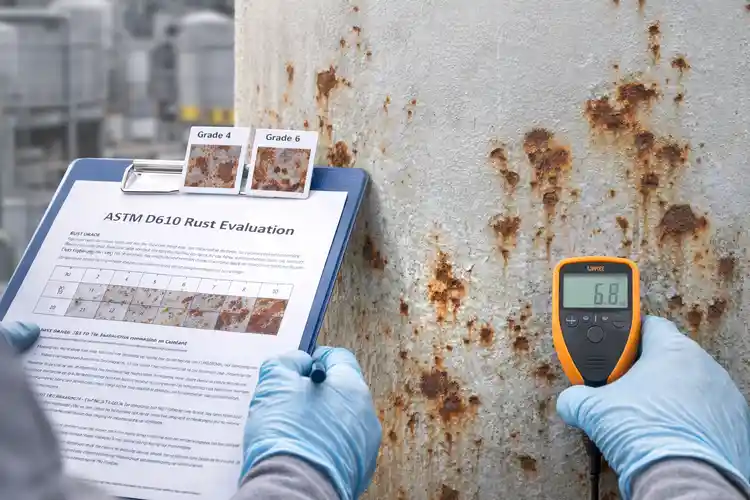

Corrosion under a paint system is one of the most critical indicators of coating failure. The ASTM D610 – Standard Test Method for Evaluating Degree of Rusting on Painted Steel Surfaces provides a standardized visual method for assessing rust formation beneath or through paint films.

Developed in cooperation with the Steel Structures Painting Council (SSPC), this method allows inspectors and coating professionals to quantify rusting using a 0–10 rust grade scale based on the percentage of surface rusted.

This guide explains the procedure, rust grading scale, interpretation, and practical application for coating inspection professionals.

Scope of ASTM D610

ASTM D610 covers:

- Evaluation of rusting on painted steel surfaces

- Visual comparison using photographic standards

- Quantification based on percentage of area rusted

It applies primarily to industrial protective coatings on steel structures.

The method does NOT address:

- Blistering

- Peeling

- Cracking

- Delamination

Only visible rust through or beneath the coating is evaluated.

Why ASTM D610 Is Important

Rusting beneath paint is a key factor in deciding:

- Whether a coating system needs repair

- Whether recoating is required

- Whether complete replacement is necessary

This test method provides:

- A standardized visual evaluation system

- Consistent reporting between inspectors

- Objective comparison of coating performance

It is widely used in:

- Oil & Gas facilities

- Marine structures

- Bridges

- Storage tanks

- Offshore platforms

- Structural steel inspection

Corrosion and Corrosion Control

Understanding the Rust Grade Scale (0–10)

The ASTM D610 rust grade scale is based on the percentage of surface area rusted.

The scale is exponential from grade 10 to grade 4.

| Rust Grade | Description | Approx. Rusted Area |

|---|---|---|

| 10 | No rusting | <0.01% |

| 9 | Minute rusting | <0.03% |

| 8 | Few isolated spots | <0.1% |

| 7 | Light rusting | <0.3% |

| 6 | Extensive rust spots | <1% |

| 5 | Moderate rusting | 3% |

| 4 | Significant rusting | 10% |

| 3 | About 1/6 of surface | ~16% |

| 2 | About 1/3 of surface | ~33% |

| 1 | About 1/2 of surface | ~50% |

| 0 | Complete rusting | ~100% |

Important Note About the Scale

- Rust grade decreases rapidly with small increases in initial rusting.

- Grades below 4 are generally considered severe and indicate major coating failure.

- Rust grades below 4 are usually not meaningful for evaluating coating performance — they indicate the coating has failed.

Procedure for Rust Evaluation

Step 1: Visual Inspection

Visually compare the painted surface with the ASTM photographic reference standards.

Step 2: Estimate Percentage of Rusted Area

Determine the approximate percentage of visible rusting.

Step 3: Assign Rust Grade

Use the rust grade scale (0–10) to assign the appropriate grade.

Important Inspection Considerations

When using ASTM D610, inspectors must consider:

1️⃣ Rust Staining vs. True Rust

Some coatings may show staining that resembles rust but is not active corrosion.

2️⃣ Dirt and Surface Contamination

Dirt accumulation can make rust assessment difficult.

3️⃣ Iron-Containing Deposits

Deposited dirt containing iron may cause discoloration that is NOT corrosion.

4️⃣ Large Area Evaluation

Failure may vary across the structure. Inspector judgment is required to select a representative rust grade.

5️⃣ Coating Color Contrast

Rust is more visible on light-colored coatings than on iron oxide or dark coatings.

Practical Field Application

ASTM D610 is commonly used during:

- Annual coating inspections

- Warranty inspections

- Maintenance planning

- Condition surveys

- Corrosion audits

It helps determine:

- Spot repair requirements

- Percentage of surface requiring blasting

- Whether overcoating is feasible

- If complete recoating is necessary

Limitations of ASTM D610

- Does not evaluate blistering

- Does not measure coating thickness

- Does not determine corrosion rate

- No precision or bias statement available

It is purely a visual estimation method.

Key Takeaways

- ASTM D610 evaluates visible rust on painted steel.

- Uses a 0–10 rust grade scale.

- Based on percentage of surface rusted.

- Widely used in industrial protective coatings.

- Essential for maintenance and repair decisions.

- Does not cover blistering or other coating defects.

FAQs

It measures the degree of visible rusting on painted steel surfaces using a standardized rust grade scale.

Rust Grade 10 indicates no rusting or less than 0.01% surface rust.

Rust Grade 4 (10% rusting) and below generally indicate serious coating failure.

No. It evaluates only visible rusting, not blistering or peeling.