A Practical Guide for Inspectors and Engineers

By Pritam Singh, QC Coating Inspector

High-temperature coatings are used on steel structures exposed to elevated service temperatures such as:

- Boilers

- Stacks

- Furnaces

- Heat exchangers

- Exhaust ducts

- High-temperature piping

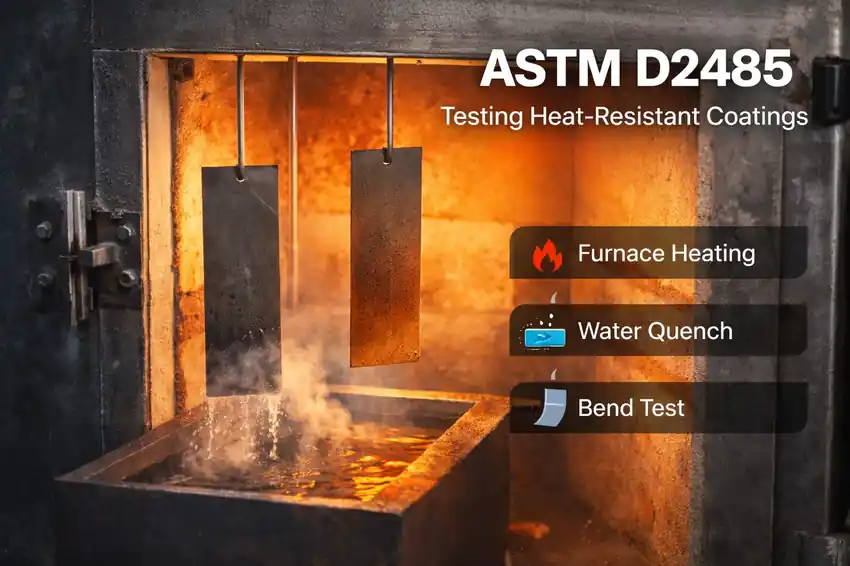

To evaluate whether a coating can withstand heat exposure without degradation, ASTM developed ASTM D2485 – Standard Test Methods for Evaluating Coatings for High Temperature Service.

This article explains the test methods, inspection principles, and practical application in oil & gas and industrial facilities.

Purpose of ASTM D2485

ASTM D2485 provides an accelerated laboratory method to evaluate:

- Heat resistance

- Adhesion retention after heating

- Film integrity under thermal stress

- Exterior durability after heat exposure

It includes two test methods:

- Method A – Interior Service Coatings

- Method B – Exterior Service Coatings

Test Method A – Interior Service Coatings

This method simulates coatings used inside heated equipment.

Procedure Summary

- Coated steel panels are heated in a muffle furnace for 24 hours at an agreed temperature.

- One panel is immediately quenched in water.

- The second panel is cooled and subjected to a mandrel bend test.

- The panels are inspected for defects.

Evaluation Criteria

Inspect for:

- Blistering

- Cracking

- Loss of adhesion

- Dulling

- Film degradation

The water quench test evaluates resistance to thermal shock.

The bend test (ASTM D522) evaluates flexibility after heat exposure.

You may also read our detailed guide on ASTM D1002 – Shear Strength Test for Single-Lap Adhesively Bonded Metal

Test Method B – Exterior Service Coatings

This method simulates outdoor high-temperature exposure.

Temperature Schedule

Panels are heated in steps:

- 205°C (400°F)

- 260°C (500°F)

- 315°C (600°F)

- 370°C (700°F)

- 425°C (800°F)

At each stage, the coating is inspected for:

- Peeling

- Cracking

- Blistering

- Discoloration

- Adhesion loss

Additional Testing After Heat Exposure

If panels pass heat testing:

1️⃣ Salt Spray Test (ASTM B117)

24-hour corrosion exposure to evaluate rust resistance.

2️⃣ Outdoor Exposure (ASTM G7)

12-month field exposure to assess weather durability.

This combination evaluates both heat resistance and corrosion resistance.

Substrate and Surface Preparation Requirements

Panels are prepared using:

- ASTM D609 – Panel preparation

- ASTM D2200 – Blast cleaning standards

- ASTM D823 – Coating application methods

- ASTM D1186 – DFT measurement

For exterior testing, panels are blast-cleaned to White Metal (SP-5 equivalent).

Proper surface preparation ensures valid test results.

Why ASTM D2485 Is Important in Real Projects

In field conditions, high-temperature coatings must:

✔ Maintain adhesion

✔ Resist cracking under thermal expansion

✔ Avoid chalking or discoloration

✔ Protect steel from corrosion

ASTM D2485 provides a standardized way to compare products before field application.

Practical Considerations for Inspectors

From field experience:

- Some high-temp coatings require heat curing during service.

- If not exposed to required temperature, performance may appear poor.

- Edge failures up to 6.4 mm are typically disregarded.

- Thickness must be controlled per manufacturer data sheet.

High-build coatings may behave differently than thin-film systems.

Common Failure Modes Observed

During testing or field service, typical failures include:

- Film cracking due to thermal expansion mismatch

- Loss of adhesion after thermal shock

- Oxidation and rusting after salt spray

- Severe discoloration

- Premature chalking

Selection of correct coating system for service temperature is critical.

Reporting Requirements

Test reports should include:

- Substrate type and preparation

- Application method

- Film thickness

- Drying/baking schedule

- Exposure temperature schedule

- Outdoor exposure location

- Observed defects

Accurate documentation ensures reproducibility.

Precision and Limitations

ASTM D2485 provides qualitative ranking rather than numerical precision.

It helps compare coatings but does not replace full-scale field validation.

When Should ASTM D2485 Be Used?

This standard is recommended when selecting coatings for:

- High-temperature piping

- Furnace stacks

- Refinery heater systems

- Power plant exhaust systems

- Boiler external surfaces

It is especially useful during coating qualification stage.

Conclusion

ASTM D2485 is a valuable evaluation tool for determining the performance of heat-resistant coatings under accelerated laboratory conditions.

For inspectors and engineers, understanding this standard helps:

✔ Evaluate coating suitability

✔ Interpret laboratory test results

✔ Specify correct coating systems

✔ Prevent high-temperature coating failures

Proper testing before application reduces costly failures in service.

FAQ

It evaluates coatings designed for high-temperature steel service.

Typically up to 425°C (800°F), unless otherwise agreed.

Yes, salt spray and outdoor exposure are included in Method B.

No, it is primarily qualitative ranking.