ASTM A385 – Standard Practice for Providing High-Quality Zinc Coatings (Hot-Dip) provides essential guidance for designers, fabricators, and coating inspectors to achieve durable, uniform, and corrosion-resistant galvanized coatings.

Unlike ASTM A123 (which specifies coating thickness requirements), ASTM A385 focuses on design recommendations, steel chemistry control, fabrication precautions, venting, drainage, and quality improvement practices to ensure successful hot-dip galvanizing.

This guide explains ASTM A385 in practical field terms for QA/QC engineers, coating inspectors, structural designers, and fabrication teams.

1️⃣ Scope of ASTM A385

ASTM A385 outlines precautions and design practices required to obtain high-quality hot-dip galvanized coatings.

It applies to:

- Structural steel

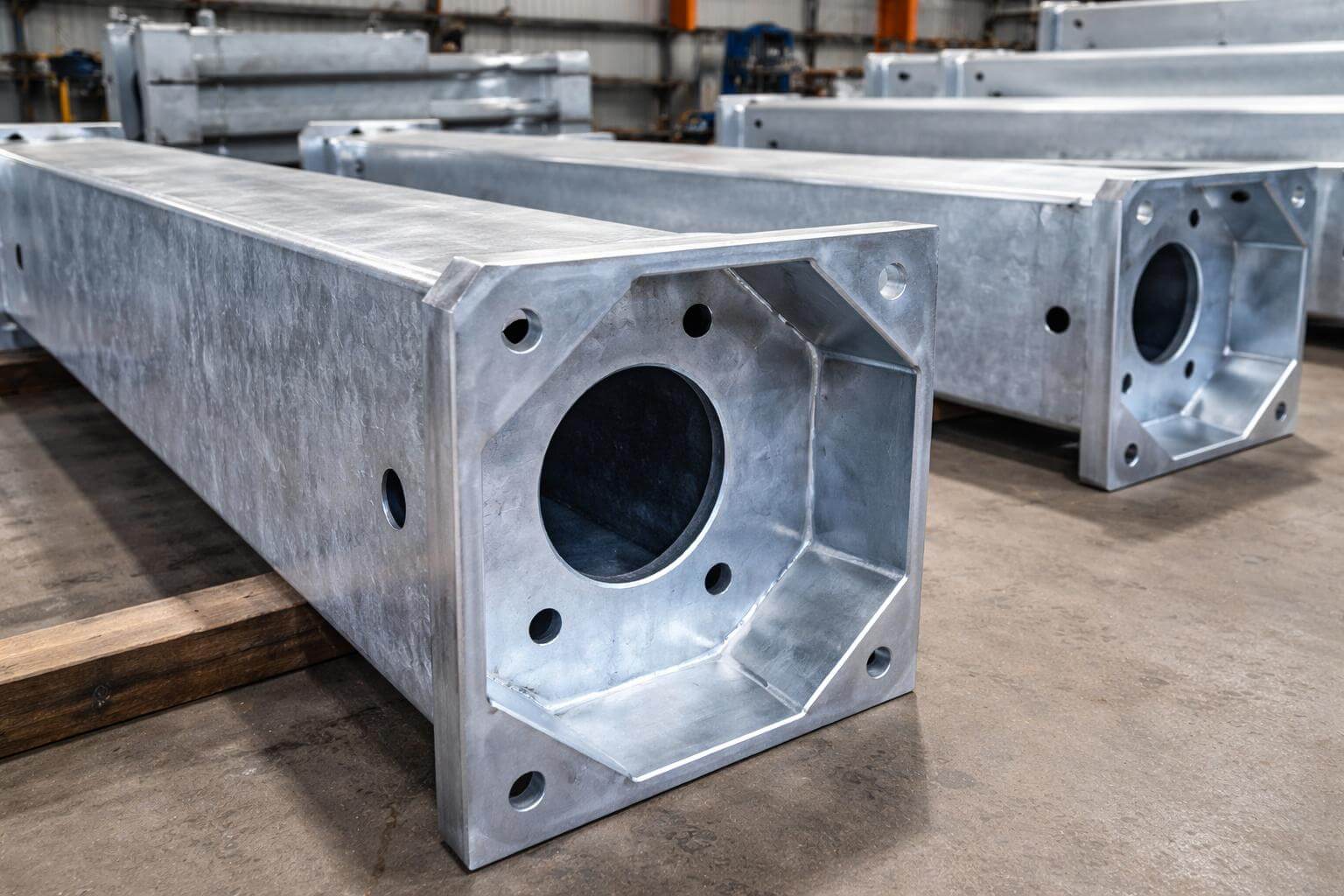

- Fabricated assemblies

- Tubular sections

- Bolted and welded structures

- Complex steel components

If project experience allows modification of any provision, changes must be mutually agreed upon between manufacturer and purchaser.

2️⃣ Steel Selection – The Most Critical Factor

Hot-dip galvanizing works through a metallurgical reaction between molten zinc and steel, forming layered structures:

- Gamma layer

- Delta layer

- Zeta layer

- Eta (outer zinc) layer

⚠️ Steel Chemistry Effects

Certain elements significantly influence coating growth:

| Element | Effect on Coating |

|---|---|

| Carbon > 0.25% | Alters coating structure |

| Phosphorus > 0.04% | Accelerates growth |

| Manganese > 1.3% | Affects thickness |

| Silicon (0.04–0.15% or >0.22%) | Causes rapid coating growth |

High silicon or combined silicon + phosphorus can produce:

- Thick coatings

- Dull gray matte finish

- Mottled appearance

- Possible brittleness

However, ASTM confirms that corrosion resistance is generally equal, even if appearance differs.

🔎 Important for inspectors: Coating appearance is not always a rejection criterion unless specified.

ASTM A123/A123M Hot-Dip Galvanizing Standard: Coating Thickness, Inspection & Acceptance

3️⃣ Assemblies of Mixed Materials

When different steel chemistries or surface conditions are combined, finish may be non-uniform.

Common causes:

- Rusted surfaces

- Pitted steel

- Machined areas

- Cast iron

- Cold-rolled vs hot-rolled steel

- High silicon/phosphorus steels

✅ Recommendation: If unavoidable, abrasive blasting of entire assembly improves coating uniformity.

4️⃣ Overlapping & Contacting Surfaces

Overlaps without seal welding are undesirable.

If gap < 3/32 in (2.38 mm):

- Molten zinc may not enter

- Cleaning chemicals may remain trapped

- Rust staining may occur

For large sealed overlaps:

- Provide vent holes

- Prevent pressure build-up at galvanizing temperature (~850°F / 454°C)

Vent size depends on:

- Overlapped area

- Steel thickness

Proper venting prevents:

- Explosions

- Incomplete coating

- Zinc entrapment

5️⃣ Vent & Drain Hole Design (Critical for Safety & Quality)

All assemblies must allow:

- Free flow of cleaning solutions

- Free flow of flux

- Air escape

- Zinc drainage

Box Sections & Tubular Members

Recommendations:

- Clip gusset corners

- Provide vent openings

- Maintain minimum 25–40% opening area depending on section size

- Internal gussets spaced minimum 36 in apart

For pipe handrails:

- Minimum 3/8 in vent hole

- Or 25% of pipe diameter (whichever larger)

Improper venting may cause:

- Explosion risk

- Coating failure

- Retained flux

- Excess zinc buildup

6️⃣ Welding & Fabrication Considerations

Welding Flux Removal

Flux residues are not removed by normal pickling. Remove using:

- Grit blasting

- Needle gun

Welding Rod Selection

Choose rods chemically similar to parent metal.

⚠️ High silicon welding rods can produce:

- Thick coatings

- Darkened weld zones

7️⃣ Warpage & Distortion

Refer to ASTM A384 for distortion control.

Uneven heating or poor design may cause:

- Twisting

- Bowing

- Dimensional changes

Design symmetry helps minimize distortion.

8️⃣ Moving Parts

When galvanizing moving assemblies:

- Provide minimum 1/16 in clearance

- Prefer galvanizing parts separately

- Post-heating may be needed for movement

Note: Post-heating may cause coating discoloration.

9️⃣ Nuts, Bolts & Threads

When bolts are galvanized:

- Nuts must be oversize tapped

- Retapping after galvanizing leaves female thread uncoated

- Male thread zinc coating provides corrosion protection

Refer to ASTM A563 for nut tolerances.

🔟 Critical Dimensions

Galvanizing adds coating thickness:

- Approximately 50 to 250 micrometres (2–10 mils+)

Design must account for:

- Pickling material removal

- Zinc thickness buildup

- Possible re-machining after galvanizing