What Is a Holiday Test in Painting?

A holiday test in painting and coating inspection is a non-destructive test (NDT) used to detect defects in a protective coating. These defects—called holidays—include pinholes, pores, voids, cracks, thin spots, or missed areas where the substrate (steel, concrete, etc.) is exposed or insufficiently protected.

Holiday testing is commonly carried out on anti-corrosion coatings applied to pipelines, tanks, vessels, structural steel, and offshore/onshore oil & gas facilities. The goal is simple: confirm coating continuity before the asset is put into service, preventing premature corrosion and costly repairs.

Why Holiday Testing Is Important

Holiday testing plays a critical role in coating quality assurance because it:

- Detects hidden coating defects not visible to the eye

- Prevents under-film corrosion and coating failure

- Ensures compliance with project specifications and standards

- Reduces long-term maintenance and repair costs

- Improves safety and service life of coated assets

In industries like oil & gas, petrochemical, marine, and power plants, holiday testing is often a mandatory inspection step.

Before conducting a holiday test, coating thickness should be verified using a DFT gauge. You can learn the complete procedure in our guide on DFT Gauge Calibration – Types, Procedure & Standards.

Types of Holiday Test for Painting & Coatings

There are two main types of holiday testing, selected based on coating thickness and substrate condition.

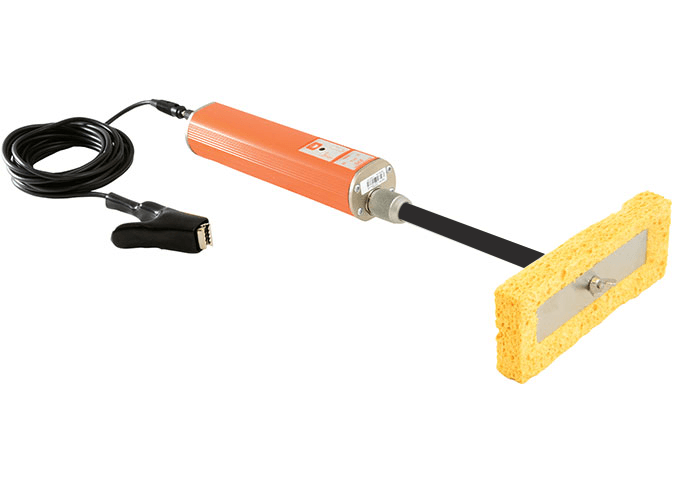

1. Low Voltage Holiday Test (Wet Sponge Test)

Principle:

This method uses a low-voltage DC current and a moistened sponge electrode. When the sponge passes over a defect, the current flows through the exposed substrate, triggering an alarm.

Typical Voltage Range:

- 5 to 90 volts DC

Suitable For:

- Thin coatings (usually up to 500 microns / 20 mils)

- Coatings applied on conductive substrates

- Internal coatings, tanks, and linings

Advantages:

- Safe and simple to operate

- No risk of coating damage

- Ideal for fresh and thin film coatings

Limitations:

- Not effective on thick coatings

- Requires a conductive substrate and a damp surface

2. High Voltage Holiday Test (Spark Test)

Principle:

This method uses high voltage DC. A probe or brush passes over the coated surface, and if a defect exists, a spark jumps through the coating to the substrate, activating an audible and visual alarm.

Typical Voltage Range:

- 1,000 volts to 30,000+ volts (depending on coating thickness)

Suitable For:

- Thick coatings (above 500 microns)

- Pipeline coatings (FBE, 3LPE, 3LPP)

- External coatings on tanks, piles, and offshore structures

Advantages:

- Highly effective for thick and heavy-duty coatings

- Can detect very small pinholes

- Widely accepted in pipeline and offshore projects

Limitations:

- Incorrect voltage can damage the coating

- Requires trained and competent inspectors

- Not suitable for wet or uncured coatings

Selection of Holiday Test Method

Choosing the correct holiday test depends on:

| Criteria | Wet Sponge Test | Spark Test |

|---|---|---|

| Coating Thickness | Thin | Thick |

| Voltage Level | Low | High |

| Risk of Coating Damage | None | Possible (if misused) |

| Typical Applications | Tanks, linings | Pipelines, offshore steel |

Standards Referenced for Holiday Testing

Holiday testing is commonly performed in accordance with:

- NACE SP0188 – Low voltage wet sponge testing

- NACE SP0274 – High voltage holiday testing

- ISO 29601 – Holiday detection for protective coatings

- Project specifications (SAES, SATIP, client specs)

Conclusion

A holiday test in painting is an essential inspection method to ensure coating integrity and long-term corrosion protection. By selecting the correct type of holiday test—wet sponge or high voltage spark testing—based on coating thickness and application, coating failures can be prevented before commissioning.

For coating inspectors, understanding holiday testing is not optional—it is a core competency in quality control and asset protection.