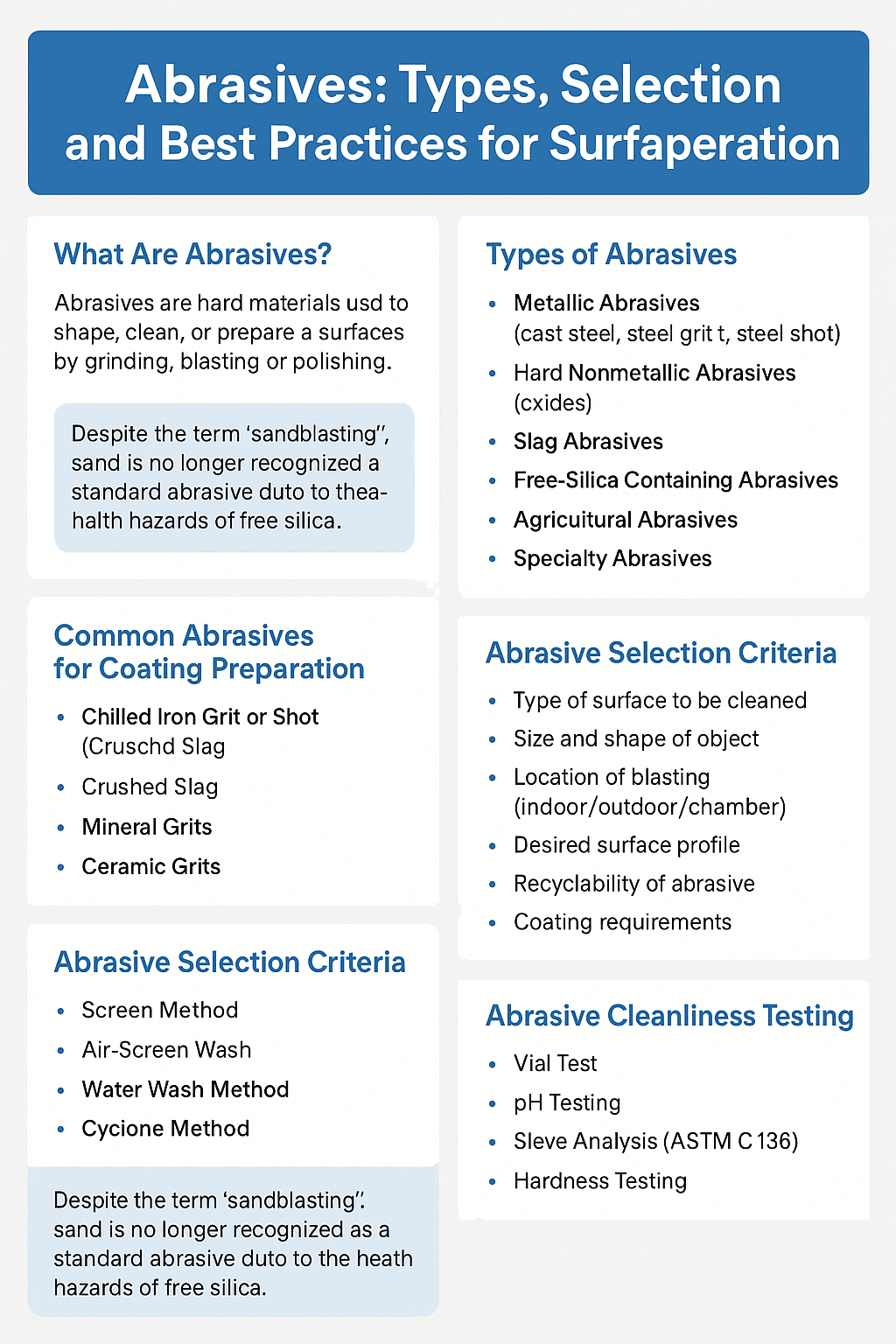

What Are Abrasives?

Abrasives are hard materials used to shape, clean, or prepare a surface by grinding, blasting, or polishing. The choice of abrasive grit significantly affects the cleaning speed and the level of surface roughness achieved.

In blasting applications, a wide variety of abrasives are used—such as walnut shells, glass beads, slags, metallic shot, and grits. However, only a select few are suitable for surface preparation before painting or coating.

Common Abrasives for Coating Preparation

- Chilled Iron Grit or Shot

- Crushed Slag

- Mineral Grits

- Ceramic Grits

Note: Despite the term sandblasting, sand is no longer recognized as a standard abrasive due to the health hazards of free silica, which can cause silicosis.

Top 10 Industrial Floor Painting Contractors in the USA (2025 Edition)

Types of Abrasives

1. Metallic Abrasives

Examples include cast steel, steel grit, steel shot, cast iron, and malleable iron.

- Steel Grit & Shot: Effective for scale removal, surface cleaning, and preparation in recycling systems.

- Cast Iron: Extremely hard, used for tough deposits but not suitable in corrosive conditions.

- Applications: Best for heavy-duty cleaning, etching, and controlled surface profiles.

2. Hard Nonmetallic Abrasives (Oxides)

These include aluminum oxide, garnet, and silicon carbide.

- Garnet: Sharp and durable, suitable for blasting rooms.

- Aluminum Oxide: Long-lasting, precise cutting, but more expensive.

- Silicon Carbide: Very sharp and fast-cutting, often used in grinding.

3. Slag Abrasives

Derived from coal, copper, and nickel refining, slag abrasives are low-cost and efficient but tend to break down quickly, making them less recyclable.

4. Free-Silica Containing Abrasives

- Sand, Quartz, Flint/Chert

Although inexpensive and widely available, these abrasives pose severe health risks due to free silica dust and are banned in many regions.

5. Agricultural Abrasives

Eco-friendly alternatives such as crushed walnut shells are used for delicate machinery, aerospace, and stainless steel applications to avoid contamination.

6. Specialty Abrasives

- Dry Ice & Ice Blasting: Effective for removing organic coatings without altering the substrate.

- Plastic Beads: Used for aerospace coatings and delicate surfaces.

- Baking Soda & Sponge Media: Gentle cleaning with minimal surface alteration.

Abrasive Selection Criteria

When selecting an abrasive, consider:

- Type of surface to be cleaned

- Size and shape of the object

- Location of blasting (indoor/outdoor/chamber)

- Desired surface profile

- Recyclability of abrasive

- Coating requirements

Abrasive Recycling Methods

Recycling reduces cost and waste, especially for expensive abrasives. Common methods include:

- Screen Method: Separates usable abrasive from dust and debris.

- Air-Screen Wash: Uses airflow to separate particles by weight.

- Water Wash Method: Removes fines and dust, suitable for non-ferrous abrasives.

- Cyclone Method: Uses suction and airflow to separate fines from reusable material.

Abrasive Cleanliness Testing

Before use, abrasives should be tested to ensure cleanliness and suitability:

- Vial Test: Detects contamination, oil, or dust.

- pH Testing: Determines acidity or alkalinity.

- Sieve Analysis (ASTM C 136): Measures particle size distribution.

- Hardness Testing: Determines durability (Rockwell or Mohs scale).